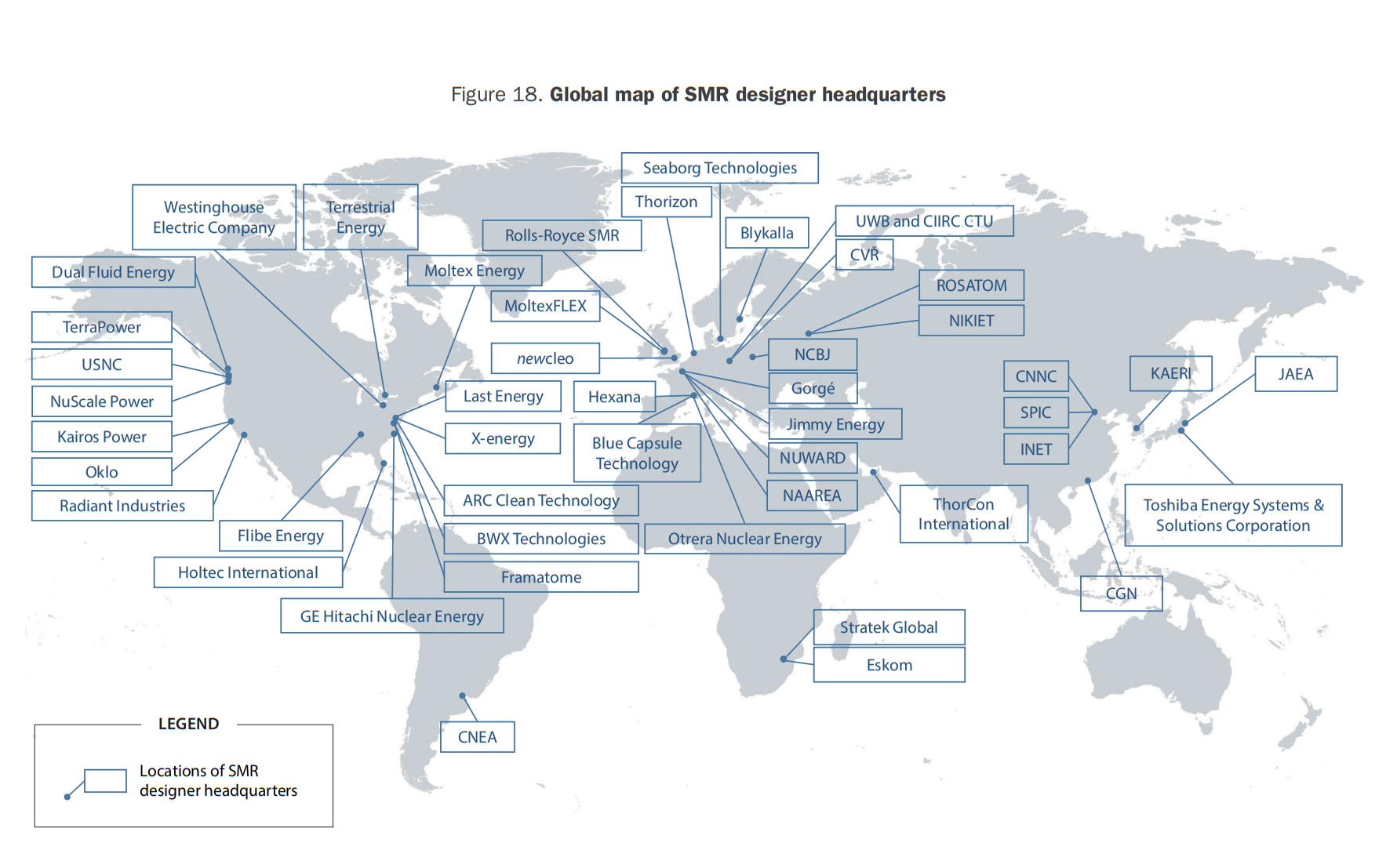

Since 2023, the global small modular reactor (SMR) industry has been undergoing a structural transformation driven by policy incentives, capital influx, and market expectations. According to the latest third edition of the SMR Dashboard published by the OECD Nuclear Energy Agency (NEA), there are now 127 distinct SMR designs worldwide, with 74 of them in stages of evaluation, licensing, or construction. This figure not only underscores the rapid global expansion of the SMR sector but also reflects a fundamental shift in national energy strategies—from centralized infrastructure megaprojects to distributed and diversified development paths.

(Image: OECD NEA SMR Dashboard)

Compared to the 98 designs recorded in the previous edition, the nearly 30% increase in designs is highly significant. It highlights not just a widening of technological pathways, but also a collective acceleration by governments and corporations to explore SMR commercialization. These designs span a broad technological spectrum, including pressurized water reactors (PWRs), heavy water reactors, high-temperature gas-cooled reactors (HTGRs), molten salt reactors (MSRs), fast neutron reactors, and microreactors, each targeting differentiated applications and performance metrics. Leading projects such as GE Vernova’s BWRX-300, Kairos Power’s Hermes, and Rolls-Royce’s PWR-based SMR are advancing through licensing and early construction phases in select countries. Their competitive advantage lies not only in modularity, but in whether they can deliver system-level innovation in safety, construction time, financing models, operation, and decommissioning, ultimately achieving economic deployability, which remains the decisive factor in SMR viability.

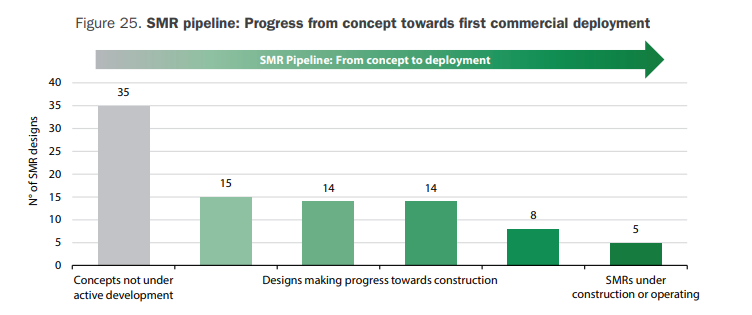

However, the surge in design numbers does not automatically indicate a healthy or mature industry. NEA Director-General William Magwood noted during the report’s launch that “only a few of these designs will actually be built.” This suggests the current SMR boom is in many ways akin to a pre-selection bubble, where the market is in the early process of sorting out potential winners through capital competition, licensing trials, and scenario-based use case exploration. Among the 127 designs, fewer than ten may actually enter commercial operation within the next five years.

(Image: OECD NEA SMR Dashboard)

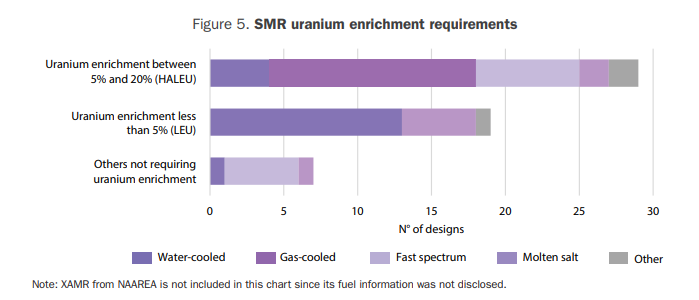

A central tension in SMR deployment lies in the question of whether lower output truly results in greater flexibility. In theory, SMRs’ compact size makes them suitable for deployment in remote areas, supporting data centers, mining camps, islanded power systems, and industrial heat applications. In practice, however, this promise is challenged by multiple barriers. One of the most critical is fuel assurance. According to NEA, over 30% of assessed designs rely on HALEU (high-assay low-enriched uranium). Yet, commercial-scale HALEU production is virtually nonexistent. The U.S.-based Centrus has only just initiated limited production, while European and Canadian initiatives remain in the early planning stages. Additionally, the broader demand for alternative fuel forms—TRISO, molten salts, and metal fuels—further strains existing nuclear fuel supply chains. Fuel uncertainty has become a major bottleneck to the advancement of many SMR projects.

(Image: OECD NEA SMR Dashboard)

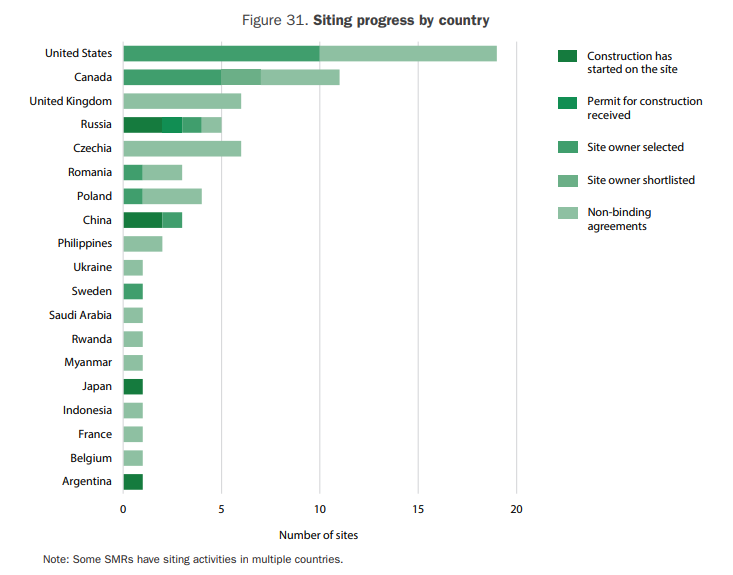

Equally challenging is the complexity of licensing and regulation. While some countries like the U.S., Canada, and the UK have made licensing progress—with NuScale’s NRC approval and Rolls-Royce’s government-backed rollout—the global framework still lacks harmonized cross-border regulatory mechanisms. This deficiency means that when designs are exported or replicated in other countries, developers must restart safety assessments, siting studies, and environmental impact reviews from scratch—driving up both deployment timelines and capital risk.

On the financing front, the surface optimism also requires nuance. While more than $15.4 billion in total commitments has flowed into the SMR space since 2024—including $10 billion in public funds and $5.4 billion in private capital—the majority of this capital is concentrated in just 4 to 5 flagship projects. Very few second-tier designs have succeeded in securing follow-on financing beyond early-stage rounds. Many remain mired in proof-of-concept loops and policy lobbying, far from entering tangible project financing or engineering kickoff.

Supply chain limitations further complicate deployment strategies. SMRs promise a shift from site-specific customization to factory-based modular construction, but in practice, this model is still unproven at industrial scale. Engineering management, quality assurance, and regulatory compliance vary significantly by region. For example, GE Vernova’s BWRX-300, though advancing in both Canada and Poland, must navigate stark differences in construction standards, pipeline materials, and environmental regulations between the two countries. Until a standardized modular engineering template emerges, the “off-the-shelf SMR” remains aspirational.

A lesser-discussed but significant risk lies in nuclear waste management. A 2022 Stanford University study argued that some SMR designs could produce 2–30 times more high-level radioactive waste per unit of electricity than large-scale reactors, due to lower neutron efficiency, novel fuel forms, and added safety redundancies. While the conclusion is debated, it underscores that SMRs are not inherently superior in waste minimization, and demand careful lifecycle planning.

(Image: OECD NEA SMR Dashboard)

SMRs are not a “silver bullet.” They are unlikely to fully replace large-scale nuclear, nor will they outcompete renewables in every scenario. Their true value lies in becoming a strategic component in low-carbon energy portfolios, particularly for grid balancing, dispatchable backup, industrial decarbonization, and hydrogen production. But to unlock this value, four critical challenges must be overcome: technology filtering, fuel assurance, regulatory coordination, and supply chain restructuring.

At this juncture, the global SMR industry stands at the threshold of a transition from quantity to quality. Whether it can achieve the first wave of successful deployments between 2025 and 2030—with standardized engineering, predictable supply logistics, and replicable financial models—will determine whether SMRs represent a passing trend or the cornerstone of a next-generation energy transition. For investors, regulators, and developers, the key question is no longer “How many SMR designs do we have?” but rather, “Which ones can survive and scale?” The race is on—and the winners have yet to emerge.